Why is the new Hilti PS1000 such a useful tool?

- Avoid damaging internal reinforcing and conduit during coring, drilling or saw cutting projects.

- Determine reinforcing bar and other object spacing and depth during structural evaluation projects.

- Determine pavement and slab thicknesses and anomalous areas (such as voids) on highway and building projects.

- Can be used in place of x-ray, without the use of harmful radioactive sources.

- Can be conducted without evacuating the area or with little site preparation.

- Can be rapidly deployed covering several locations per day, saving time, reducing overall project cost, and reducing the potential of cutting or drilling into concrete reinforcements.

- Can locate live electrical wires in the concrete

What is concrete scanning?

The concrete scanner is used to locate reinforcing steel, electrical conduits, post-tensioned cables, metal and plastic conduits, glass-fiber cables, wood, and voids in concrete structures up to 12 inches deep. It is also used to evaluate existing floor slabs, bridge decks, balconies, tunnels, and post-installed rebar connections and to check slab thickness.

How does the Hilti PS1000 work?

The PS1000 uses ground penetrating radar (GPR) to image targets that are different than the concrete being scanned. GPR sends high frequency radio waves into the subsurface and measures the travel time for the returning reflection. Reflections are caused by a change in material.

The PS1000 uses ground penetrating radar (GPR) to image targets that are different than the concrete being scanned. GPR sends high frequency radio waves into the subsurface and measures the travel time for the returning reflection. Reflections are caused by a change in material.

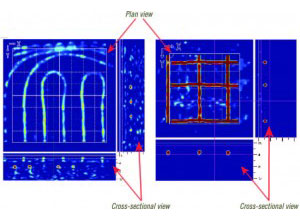

The three antenna system offers the only top down plan view in the market along with a cross-sectional view for easier data interpretation. The array collects a six inch wide area with one swipe, allowing for faster and more accurate results. The scanner is also equipped with an EM senor that allows detection of live electrical cables to a depth of 3 inches at low and medium current levels. Higher current levels are possible to detect deeper in the slab. When working around live currents, the EM sensor is a great added level of protection. Data can be viewed on a field monitor in 3D and PDF’s can be created for reports.

The PX10 transpointer tool is used to transfer the starting point for drilling through-holes to the other side to reduce the risk of hitting obstructions. It also has the ability to measure the total wall or ceiling thickness, regardless of material type.

For more information on CMT, NDT services or specifically on the Hilti Concrete Scanner contact your CMT Manager. Justin Donovan in Memphis, Tennessee; Steve Damron in Overland Park, Kansas; Luke Heuerman in Fairview Heights, Illinois or Jeff Klein in St. Louis, Missouri.