St. Louis MSD Combined Sewer Overflow

Location: St. Louis, Missouri

Client: Jacobs

Services: Drilling, Geophysics, Geotechnical

Overview:

Metropolitan Sewer District (MSD) has begun its $4.7 billion, 23-year, wastewater/stormwater system overhaul. This project was launched for remediating the combined sewer system originally built before the Civil War — the first system to be built west of the Mississippi River. The system needed to be improved to be compliant with USEPA and MDNR standards. These improvements will include technology updates, new sewer separators, and construction of new conveyance and storage tunnels.

St. Louis MSD Combined Sewer Overflow Project Background

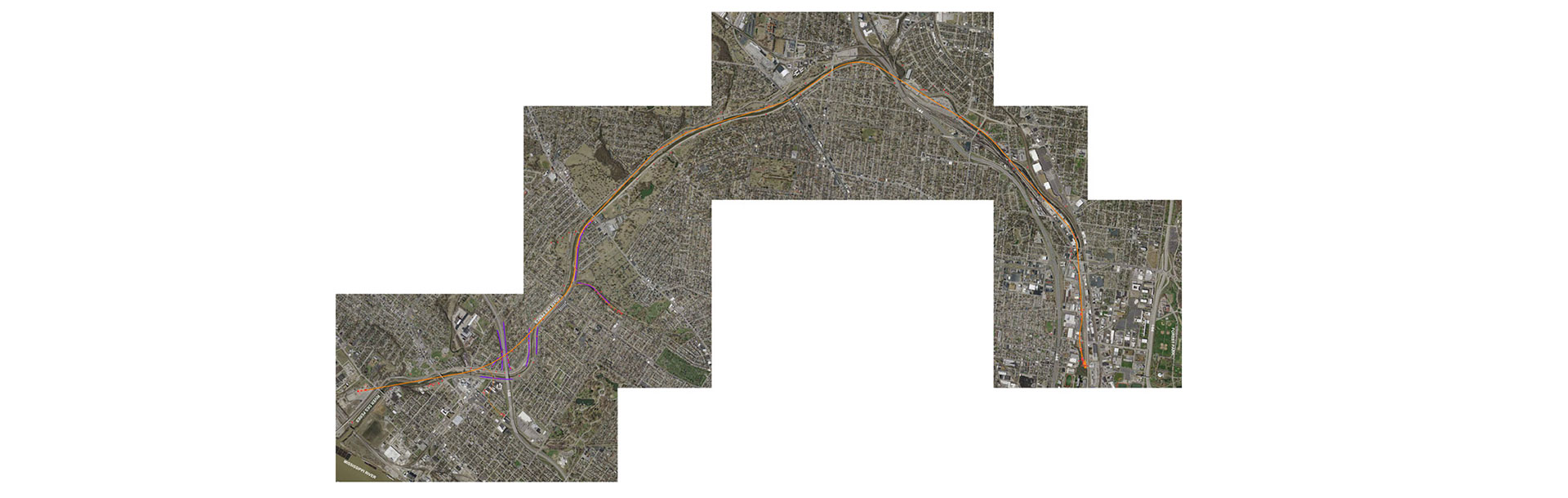

The Lemay RFM was the initial phase of the overall combined sewer overflow (CSO) remediation. The Lemay Redundant Force Main (RFM) project was a second force main from the Lemay Pump Station #1 to the Lemay Waste Water Treatment Plant (WWTP). This provided additional conveyance capacity. The RFM alignment roughly paralleled the existing force main and was located slightly deeper in profile. The RFM was planned as a nominal 10-foot diameter tunnel, 3,262 feet long through bedrock.

Geotechnology provided geotechnical, field and laboratory testing, and geophysical surveys for the RFM. We also prepared a geotechnical data report that provided critical information for the geotechnical aspects of design and construction of the RFM.

To date, Geotechnology’s services have included a subsurface exploration performed along the alignment of the Lemay RFM that included drilling 12 deep borings and 17 probe borings. The deep borings, on an approximate 500-foot spacing, were nominally 145 feet deep. They also included NQ3 coring technology and packer testing through the full rock-core interval. Borings were drilled with CME 55 and 550 rotary drill rigs using 3-3/4” hollow stem augers and rotary wash techniques to the top of bedrock.

Split-spoon and Shelby tube samples were obtained in the deep borings while the probe borings were speed drilled to refusal to probe the top of bedrock. Borings were backfilled with tremie-placed, cement-bentonite grout. In addition to routine soil and rock laboratory testing, Geotechnology performed Cerchar abrasion and Brazilian tensile. We also conducted point load tests on rock core samples.

Geophysical Surveys

As the project progressed, the design team evaluated as-built utility records and on-site observations. Additionally, we requested verification of the force main location. We performed two methods of geophysical surveys to ascertain accuracy of the plans. These methods were spontaneous potential (SP) and electrical resistivity. SP is often used to detect the location of water movement underground. Resistivity methods are used to locate subsurface voids or fracture zones.

Results of the geophysical surveys showed that the existing force main was 50 feet closer to the planned entry shaft than as-built utility location records indicated. This closer proximity led to the teams’ decision to move the entry shaft approximately 90 feet. This move lengthened the RFM tunnel but increased the distance from the existing force main to the planned entrance shaft excavation. By moving the entrance shaft, the potential of the force main being compromised during excavation was significantly reduced.